Professor to explore microgravitational printing of semiconductors through NASA-supported parabolic flights

Published: May 1, 2024 7:52 AM

By Joe McAdory

Can a small, laser ablation and sintering enabled (LASED) multi-material printer operate in microgravity? Masoud Mahjouri-Samani, the Goldbold Associate Professor in the Department of Electrical and Computer Engineering, will find out next spring through a series of NASA-supported parabolic flights.

The purpose: to prove the space functionality of a specially designed LASED multi-material printer capable of printing various materials, including semiconductors, metals and insulators that can be used to make electronics and semiconductor devices in gravity-challenged environments.

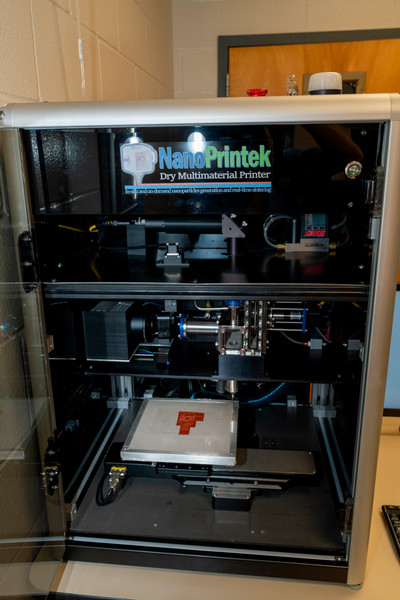

“When it comes to space manufacturing, we need sustainable technology that is compatible with the space environment,” said Mahjouri-Samani, founder of NanoPrintek, Inc., an Auburn-based startup that creates disruptive LASED multi-material printing technology for electronics, energy, biomedical and sensing applications. “With printed electronics, the entire industry has been based on wet ink, but ink and liquids are not compatible with space or microgravity environments.

“Our dry LASED multi-material printer also does not require post-processing, a procedure that typically necessitates the use of ovens and/or heaters, which have their own challenges in the space environment. This supply chain-resilient and sustainable technology is an energy-efficient and environmentally friendly process that will open a new realm of manufacturing in space. I am proud that this technology was invented in my lab and doesn’t exist anywhere else worldwide.”

The project, “In Space Dry Printing Electronics and Semiconductor Devices,” recently received a $870,000 grant from NASA to pursue new manufacturing frontiers.

The technology uses in-situ laser ablation to generate pure and dry nanoparticles from solid materials. Next, the nanoparticles are flown out of the printer nozzle and laser sintered in real time to print various multi-material electronics and semiconductor devices.

“This research is part of the cornerstone of a space manufacturing center that we've discussed for more than a year,” said Brock Birdsong, director of research at the Auburn University Applied Research Institute. “It will help establish space manufacturing in Huntsville and fulfills that relationship between the Applied Research Institute back to campus, where we're administering the research to solve applied problems. This project also fits very well into our goals for our relationship with NASA, which is luckily in our proximity.”

Mahjouri-Samani and Birdsong agreed that the first step before printing in space, is printing in microgravity.

“Then the international space station. Then the moon. Then maybe Mars,” Birdsong said.

Enter next spring’s microgravitational-inducing parabolic flights. Mahjouri-Samani said he and a team of researchers will test the system aboard an aircraft off the east coast of Florida.

The aircraft will execute a series of about 25 parabolas, each achieving microgravity for 20 seconds.

During this time, Mahjouri-Samani’s printer will function, as directed — while floating.

“We will be printing materials on lines and patterns,” he said. “Then we will compare those results to what we already printed under the Earth’s gravity. We will print precisely the same lines here, and when we go into microgravity, we will repeat that. When we return, we will perform a series of tests on the printed parts and ask ourselves, ‘How did this behave?’ ‘How does it compare to the other counterparts?’ ‘Which one is better?’ And if microgravity is better, then ‘why?”.

Mahjouri-Samani believes the revolutionary technology can be used not only in space for space manufacturing but also in space for earth manufacturing.

“If we can print better metals, semiconductors, and devices in space, then we might be able to enable new capabilities for terrestrial applications,” he said. "The space opens up a new realm of manufacturing ecosystem, with, of course, the right technology.”

Media Contact: , jem0040@auburn.edu, 334.844.3447

Masoud Mahjouri-Samani, associate professor in electrical and computer engineering, works with graduate student Aarsh Patel.