If you’re trying to gauge Auburn’s preeminence in harsh environment electronics resiliency development and flexible hybrid electronics (FHE) research, look no further than the latest project call of the NextFlex National Manufacturing Institute.

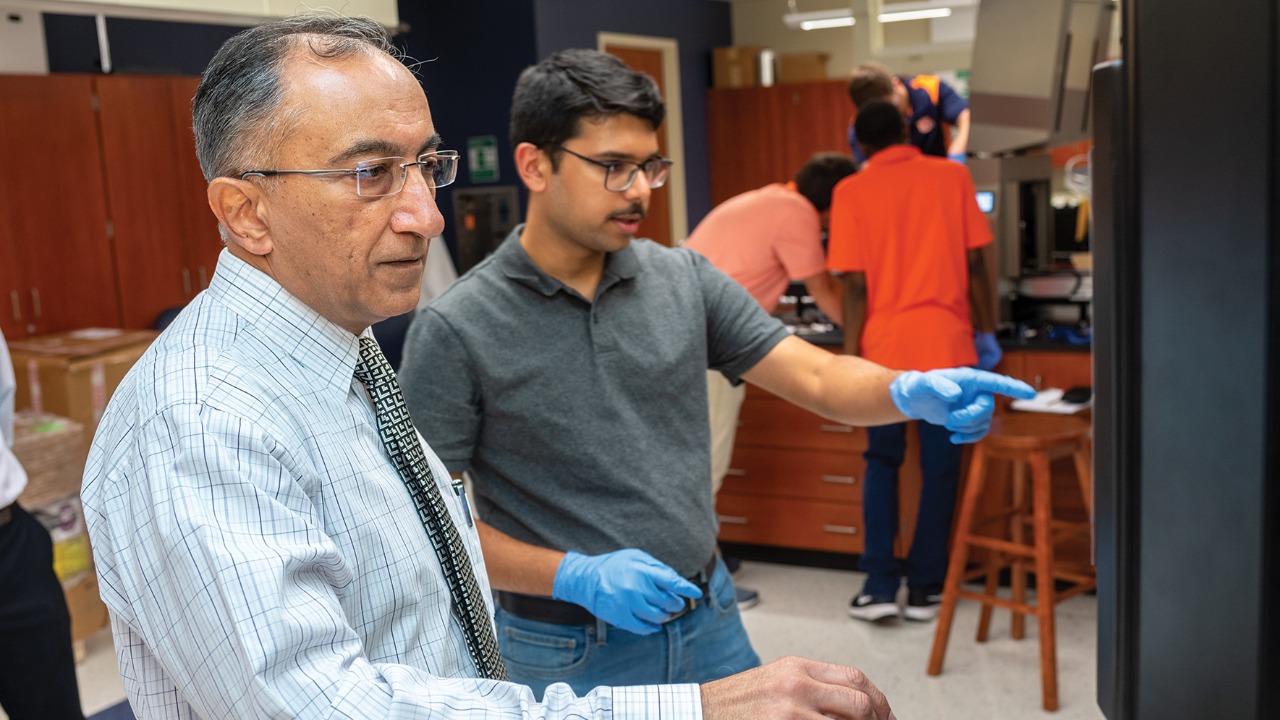

In the Project Call 7 competition, there were two winning Auburn proposals. In the current Project Call 8? Three, collectively funded at $2.5 million with 1:1 cost-share — all focused on additively manufactured (AM) FHE, all competitively won by teams led by Pradeep Lall, the MacFarlane Distinguished Professor and Alumni Professor of mechanical engineering and director of Auburn University Electronics Packaging Research Institute (EPRI).

Under Lall’s 15-year leadership, Auburn’s FHE work has grown exponentially. In 2015, he led the Auburn team contributing to the winning proposal that resulted in the foundation of the NextFlex National Manufacturing Institute. Auburn is a tier-1 founding member of NextFlex, whose mission is to advance U.S. manufacturing of FHE; Lall serves on the NextFlex technical council and has previously served on the governing council of the institute.

The design of electronics for operation in harsh environments has long been an area of EPRI. While earning an international reputation for designing electronics for operation in harsh environments relative to automotive, military, defense and downhole applications, Lall has also accelerated the growth of the flexible hybrid electronics industry itself. He expects the three programs to also benefit EPRI’s leading work toward developing FHE reliability standards.