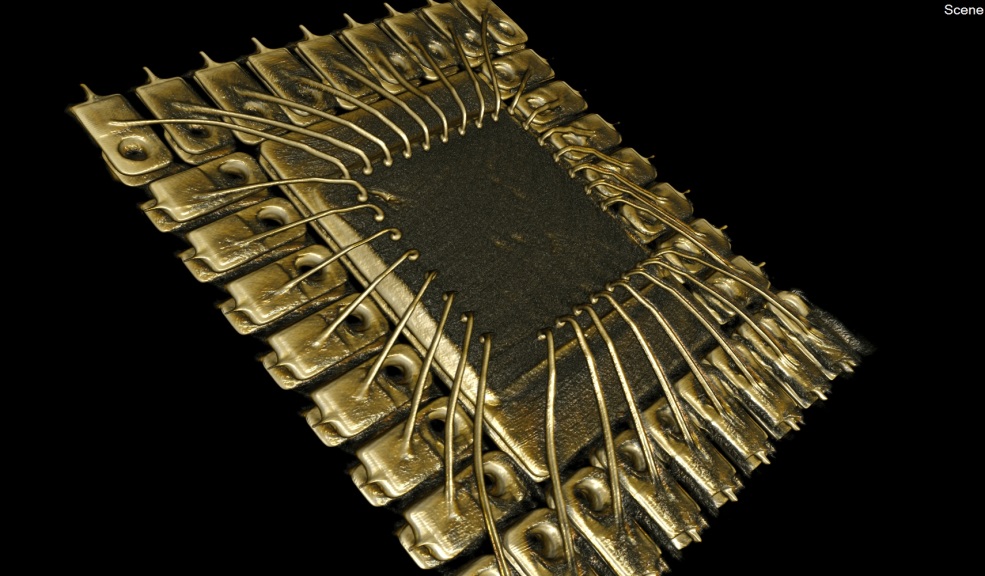

Pradeep Lall, Thomas Walter professor of mechanical engineering and director of Auburn’s NSF Center for Advanced Vehicle and Extreme Environment Electronics, is researching a copper-aluminum wire bond system for cost-effective, next generation electronics through grants from the Semiconductor Research Corporation and the U.S. Army Aviation and Missile Research Development and Engineering Center. Wire bonding in electronics, which predominantly uses gold wires, is used extensively in semiconductor packaging for chip interconnections. The increase in the price of gold has motivated the industry to search for alternatives to gold wire, and a transition has been made to use copper wire bonding technology. Potential advantages of this transition include the lower cost of copper wire, lower thermal resistivity and lower electrical resistivity, as well as higher mechanical strength and higher deformation stability compared to gold wire. The shift to copper wire brings along a number of risks such as higher hardness compared to gold wire, narrow process windows and susceptibility to oxidation during the ball formation process. Problems encountered with copper wire bonding technology encompass cracking of the wire bond interface under extended exposure to humidity and temperature. Lall is studying the reliability and prognostic indicators for the copper-aluminum wire bond system.

Pradeep Lall, Thomas Walter professor of mechanical engineering and director of Auburn’s NSF Center for Advanced Vehicle and Extreme Environment Electronics, is researching a copper-aluminum wire bond system for cost-effective, next generation electronics through grants from the Semiconductor Research Corporation and the U.S. Army Aviation and Missile Research Development and Engineering Center. Wire bonding in electronics, which predominantly uses gold wires, is used extensively in semiconductor packaging for chip interconnections. The increase in the price of gold has motivated the industry to search for alternatives to gold wire, and a transition has been made to use copper wire bonding technology. Potential advantages of this transition include the lower cost of copper wire, lower thermal resistivity and lower electrical resistivity, as well as higher mechanical strength and higher deformation stability compared to gold wire. The shift to copper wire brings along a number of risks such as higher hardness compared to gold wire, narrow process windows and susceptibility to oxidation during the ball formation process. Problems encountered with copper wire bonding technology encompass cracking of the wire bond interface under extended exposure to humidity and temperature. Lall is studying the reliability and prognostic indicators for the copper-aluminum wire bond system.

Into the Lab

Into the Lab: Mechanical

Tags: Auburn Engineering × Auburn University × copper wire × gold bonding × mechanical engineering × Pradeep Lall × Samuel Ginn College of Engineering × wire bonding