In March, NASA awarded Auburn University’s National Center for Additive Manufacturing Excellence (NCAME) a $5.2 million contract for work on the Rapid Analysis and Manufacturing Propulsion Technology project, or RAMPT.

It was just the latest in a growing list of AM industry headlines testifying to Auburn’s quickly established status as an international hub for additive manufacturing.

“NCAME currently has over 70 partners,” said NCAME director Nima Shamsaei, distinguished associate professor in mechanical engineering, and principal investigator for RAMPT. “We’re going after funding opportunities to help the industry and the government in faster adoption of this emerging technology.”

NASA, which partnered with the university to establish NCAME in 2017, needs to adopt it faster than most.

Forget 2028, Vice President Mike Pence said during his March 26 Huntsville speech at the fifth meeting of the National Space Council — America would return to the moon within five years, not nine. It wasn’t a prediction. It was an order.

“For more than 60 years, Huntsville, Alabama, has built the finest rocket propulsion systems in the world,” Pence said. “And we want to ensure it remains that way for the next 60 years.”

Enter NCAME, which through RAMPT is working on evolving light-weight, large-scale 3-D printing techniques for the development and manufacturing of regeneratively-cooled thrust chamber assemblies for the liquid rocket engines necessary not only to return Americans to the moon, but to put the U.S. in the pole position for the race to Mars.

“We believe that when we land on the moon in 2024, our lander will be powered by an additively manufactured engine nozzle designed and developed right here in Alabama,” Mike Ogles, director of NASA programs in the Samuel Ginn College of Engineering, told NASA brass and congressional staffers in a June meeting.

Ogles also serves as project manager for RAMPT

“In order to meet the Vice President’s expectations, we need to further develop key technologies such as additive manufacturing, and what NCAME will be doing on the RAMPT project will help us develop the next generation of liquid rocket engines,” Ogles said. “The key to be able to get to the moon and then to Mars is how much payload the rocket can take. You have to make the engine as light as possible, and with additive manufacturing techniques we can design rocket engines that have higher performance with a lower weight.”

But Paul McConnaughey, deputy director of Marshall Space Flight Center, is quick to point out that NCAME’s research will improve more than just space travel.

“This partnership with Auburn University and industry will help develop improvements for liquid rocket engines, as well as contribute to commercial opportunities,” McConnaughey said. “The technologies developed by this team will be made available widely to the private sector, offering more companies the opportunity to use these advanced manufacturing techniques.”

For now, though, the primary objective isn’t the private sector — it’s the solar system.

“When we look back in five years, we’ll be able to say that Auburn played a role in taking us back to the moon and putting us on Mars,” Ogles said.

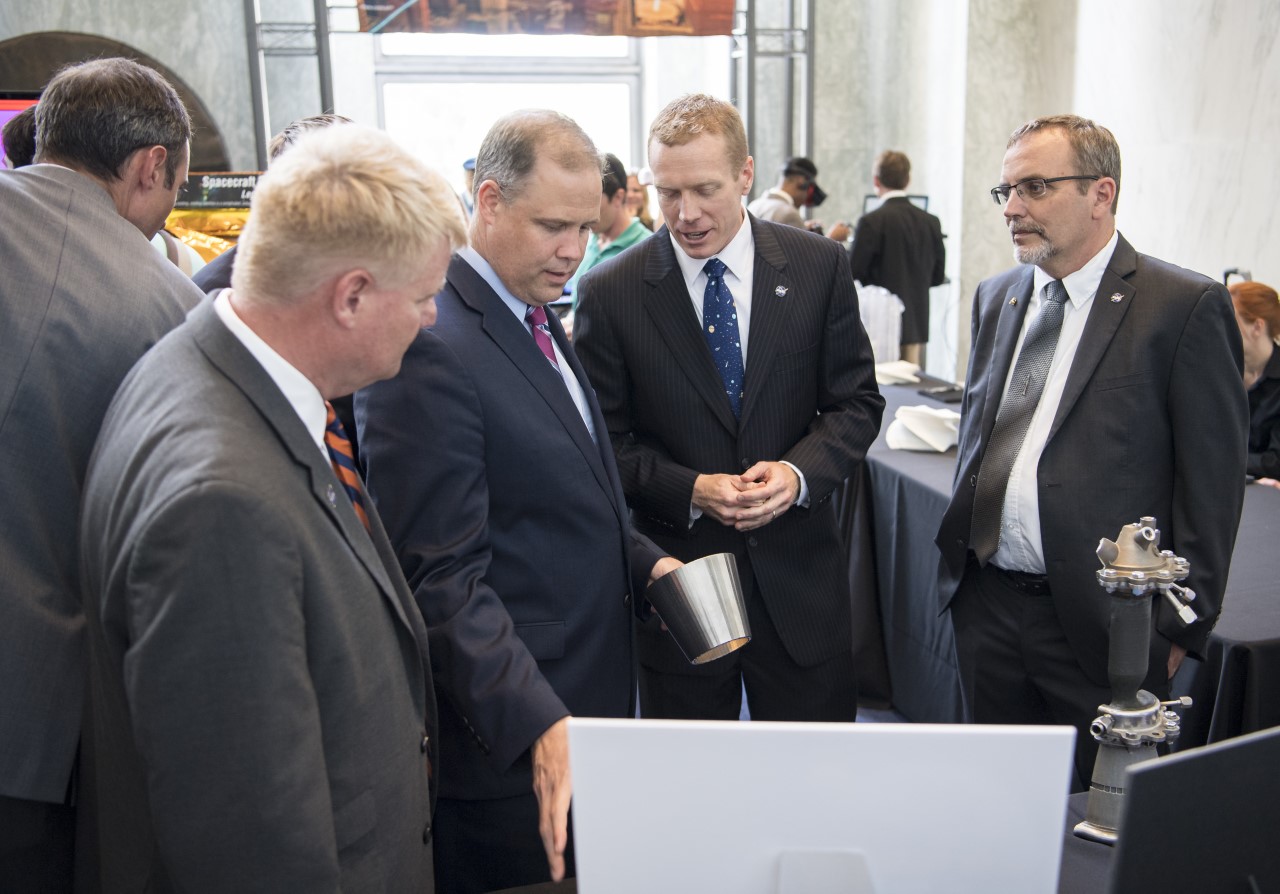

If his recent conversation with NASA Administrator Jim Bridenstine is any indication, others will be saying it, too. In June, Ogles represented RAMPT at the NASA Technology Day on the Hill, a fuel nozzle manufactured through direct energy deposition in tow. Bridenstine introduced himself, picked up the nozzle and listened to Ogles’ updates on NCAME’s research.

Then he put the nozzle down and looked at Ogles.

“War Eagle,” he said.