Faculty member Yasser Gowayed and graduate student Essam Abouzeida, along with faculty members George Flowers and Lewis Payton in mechanical engineering, are working to construct advanced fibrous composite airplane wings. They are collaborating with NASA’s Dryden Flight Research Center and the Intelligent Fiber Optic Systems Company to manufacture a polymer composite wing that features online fiber optic sensors which help study the wing’s movement and responses during flight.

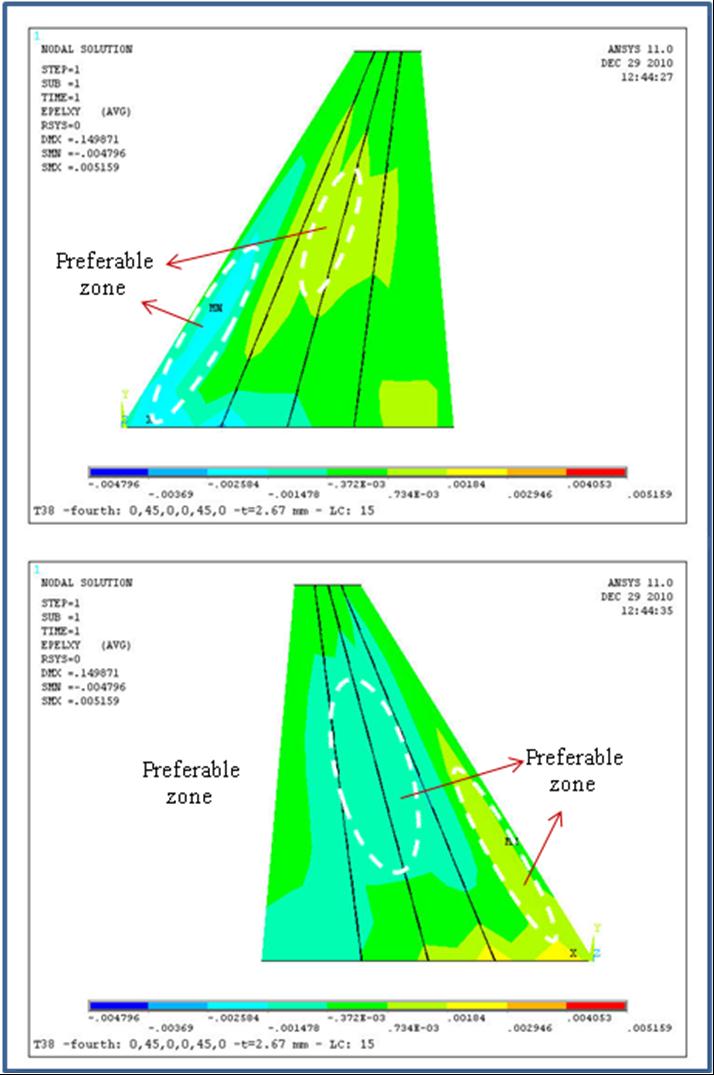

Gowayed and his team are developing mechanisms and procedures for the wing’s design, manufacture and testing, as well as how it can be instrumented with Fiber Bragg Grating (FBG) optical sensors that reflect some wavelengths of light while blocking others.

Their work demonstrates a new generation of FBG-based structural monitoring systems that can be used to detect and locate superficial cracks and tears, as well as deeper structural problems, in composite wings that are exposed to harsh conditions.

Using these new sensors makes it possible to analyze the wing without damaging or disturbing it during testing. Their work will help improve the effectiveness of flight testing by enhancing and simplifying sensor installation and measuring new parameters for composite airplane wings.