The manufacturing industry is projected to have two million job vacancies by 2025. The Interdisciplinary Center for Advanced Manufacturing Systems (ICAMS) aims to change that statistic.

Armed with a $1.7 million award from the U.S. Department of Defense (DOD), ICAMS plans to visit more than 28,000 sixth-grade students in Alabama throughout the next two years with the revival of the Bird Inc. program.

What is Bird Inc.?

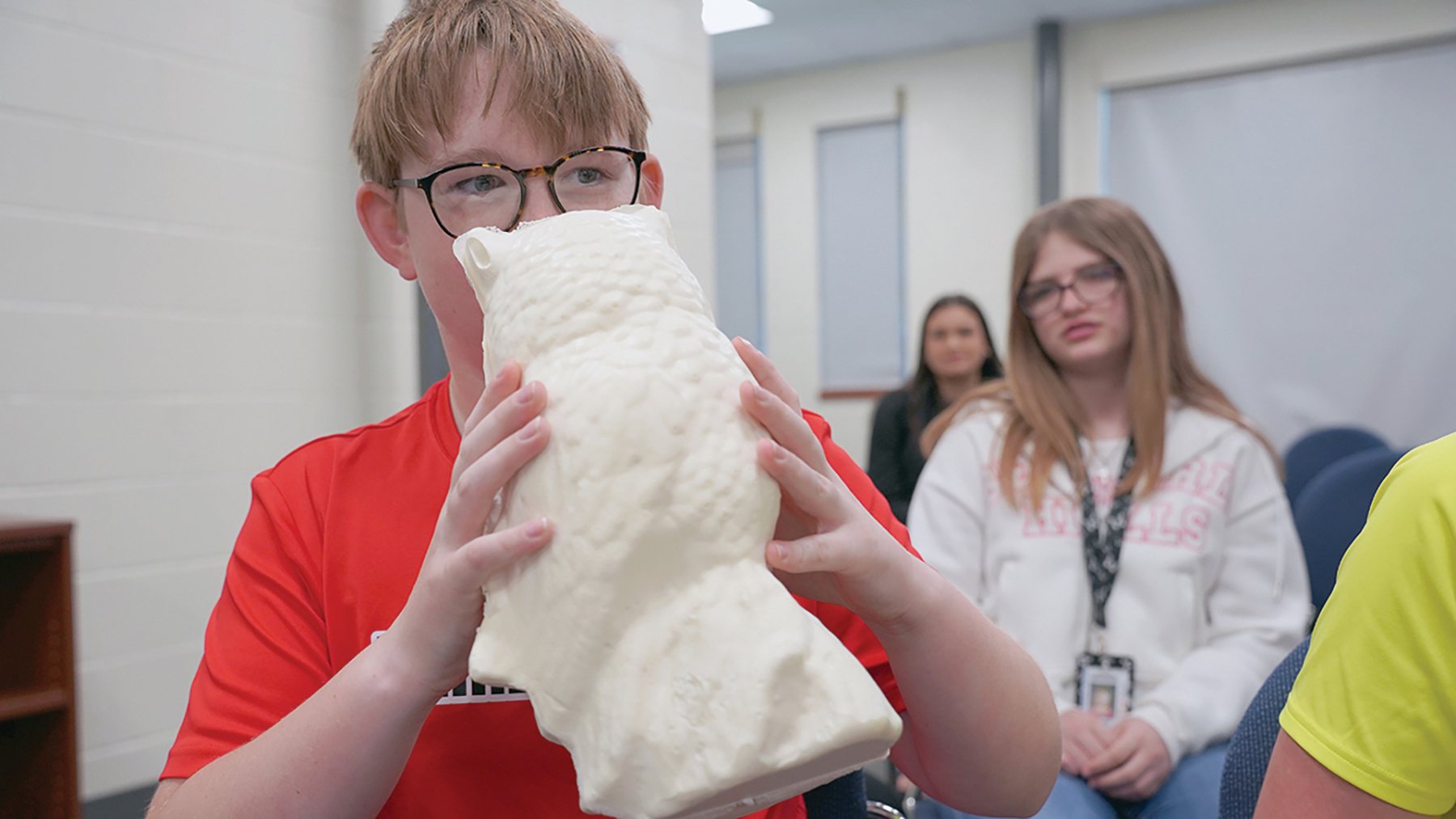

Bird Inc. is a 50-minute classroom activity that simulates a manufacturing environment created by John Cranston in 1996 to broaden students’ perspectives on potential manufacturing jobs after high school.

Students participate in a classroom business, which includes roles such as company president; sales and marketing professional; engineer; tool and die machinist; technician; and quality control specialist. The rest of the class acts as potential investors.

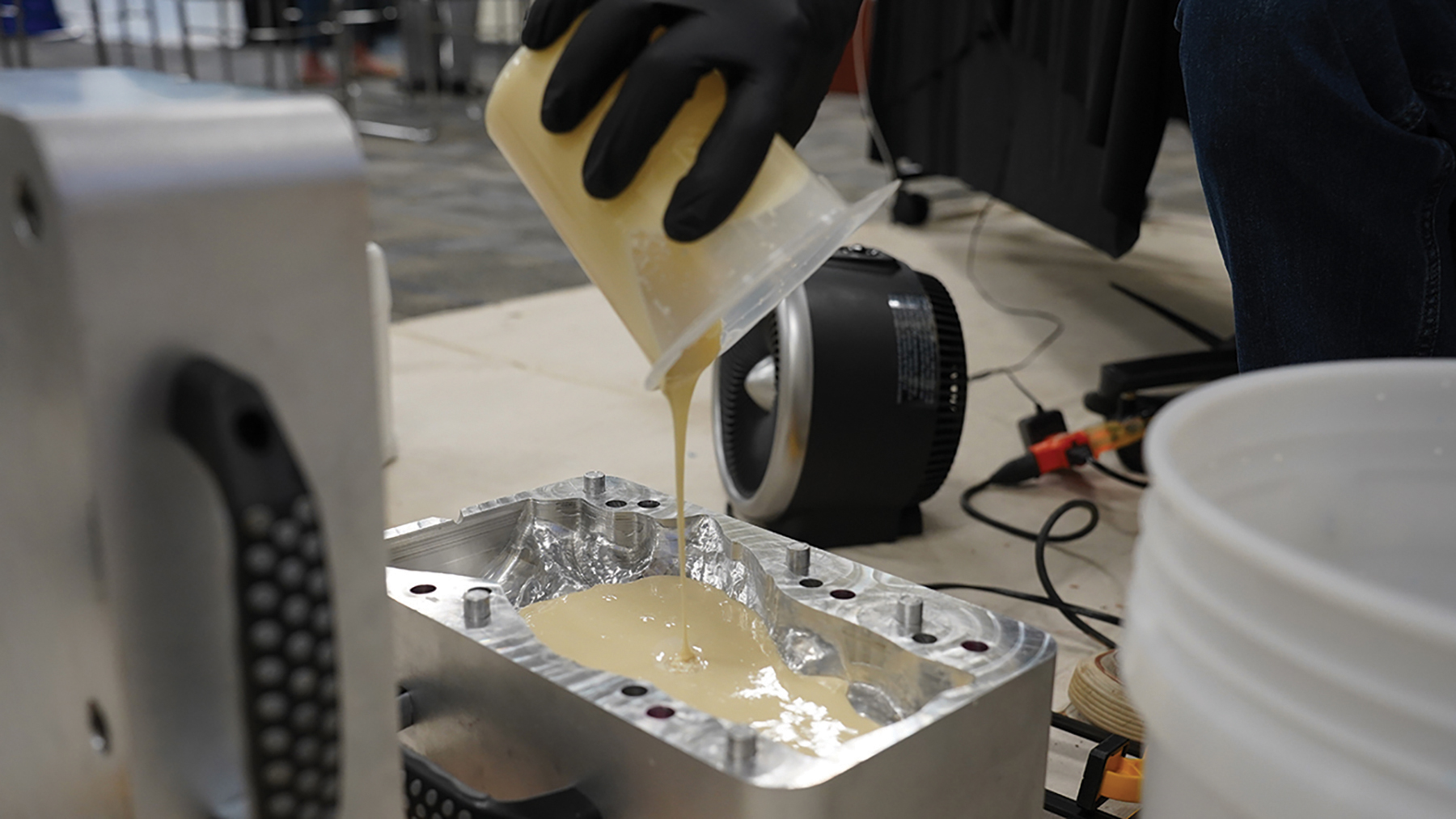

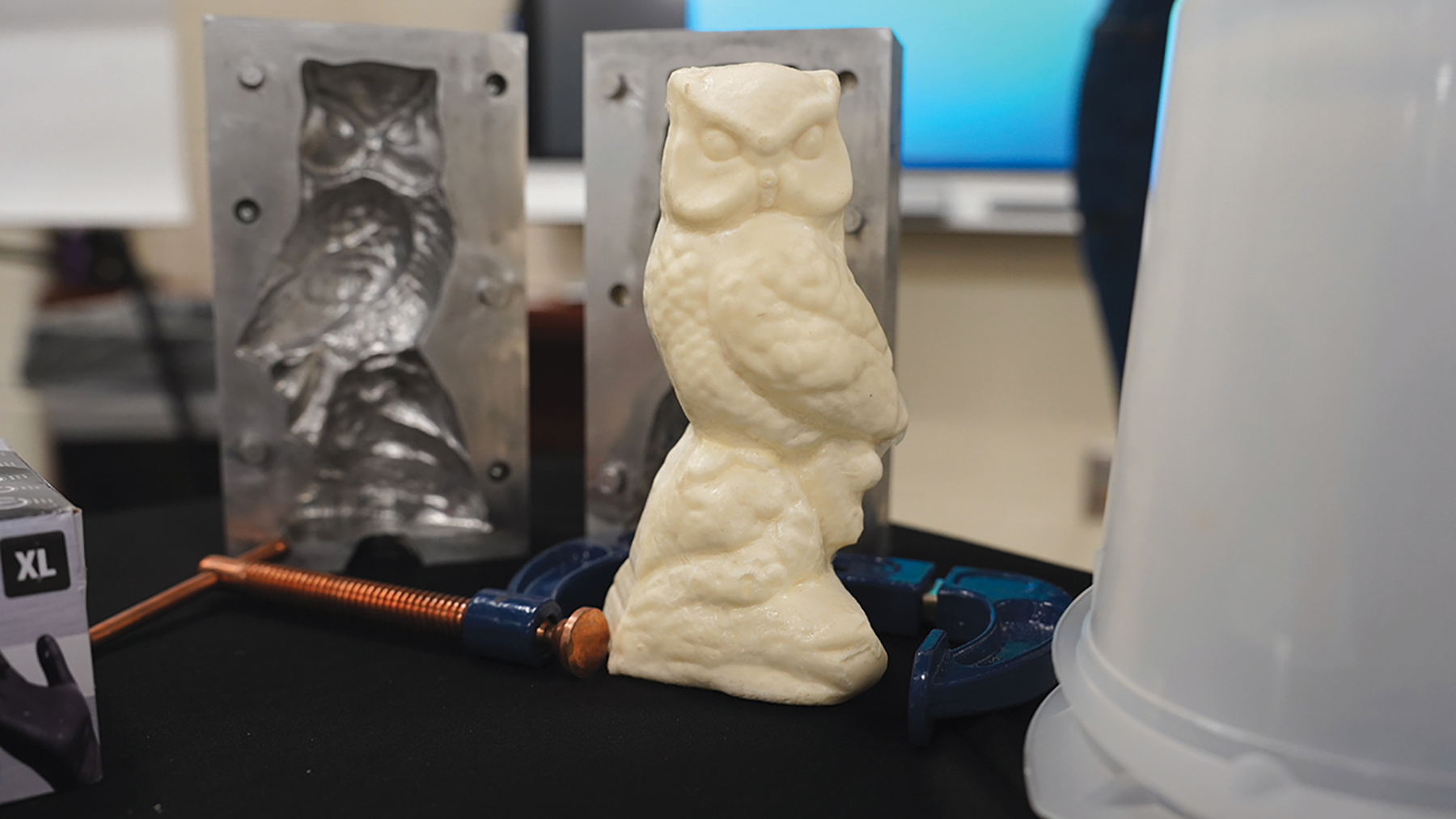

According to Kyle Castellano, Bird Inc. program manager, the classroom activity is primarily a hands-on manufacturing activity, where students learn to mix chemicals, pour them into molds and calculate production rates and costs. The hands-on approach is to not only teach practical skills but also foster teamwork and problem-solving as students navigate the challenges of running a business.

At the end of the activity, students produce a rigid foam polyurethane decoy owl using a two-piece mold developed by ICAMS and determine whether their business was booming.

“We teach them important business concepts they can use in their lives, such as profit and loss, marketing and manufacturing real products,” Cranston said.

Bird Inc. was made possible after President Bill Clinton signed the School-to-Work Opportunities Act in 1994. Cranston presented the program from 1994-2004 with funding from the University of Alabama in Huntsville and then continued it independently until 2008.

ICAMS revived the program in 2023 as a beta project at J.F. Drake Middle School in Auburn. The program introduced more than 700 sixth-graders to concepts related to science, technology, engineering and mathematics jobs.

Castellano said one of the critical aspects of the activity is the realistic business simulation. Students quickly learn the financial implications of their decisions, such as setting salaries and managing production costs. This often leads to lively discussions and problem-solving sessions where they must figure out how to keep their fictional company profitable.

The project also emphasizes the importance of having a backup plan. Presenters encourage students to consider alternative educational paths, such as technical schools or trade certifications, if traditional college routes do not work out.

Manufacturing Focused

Greg Harris, director of ICAMS and chair of the Department of Industrial and Systems Engineering, said value is created in manufacturing.

“We take ideas and raw materials and turn them into products people desire and pay for through manufacturing processes,” he said. “Innovation takes place where the work is done. We need to share these ideas with students and allow them to choose careers in this value-creating industry. Bird Inc. is a great way to introduce the next generation of the workforce to the manufacturing business enterprise.”

With the new DOD grant, Bird Inc. will be showcased in two Alabama Workforce development regions: Region 1 (North Alabama) and Region 5 (East Central Alabama).

According to Castellano, ICAMS hopes to reach 48.5% of Region 1’s and 75% of Region 5’s sixth-grade populations in the next two years.

“There is a lack of people entering the manufacturing field in this country, and we need more individuals in this sector for national security reasons — to support projects that require American workers for American DOD projects,” Castellano said.

Harris said the U.S. industrial base is the foundation of the country’s freedom.

“We learned during the pandemic that it is detrimental to our society when we cannot manufacture the things we need,” he said. “A strong industrial base is necessary to ensure we are ready when the country needs our manufacturing capabilities to provide the systems required for national security.”

Structure of the Program

Cranston will stay on the project as the state coordinator. He will help hire and train three additional presenters to travel around the workforce development areas to deliver the program. His role will also include developing a sustainability plan to expand Bird Inc. into additional Alabama regions and other states.

Castellano said ICAMS will create a Bird Inc. organizational structure and playbook to show how the program works and why it is vital to move forward. He said the playbook is essential for the program to grow not only into a state program but also a national program.

The key to the playbook is the presentation kit, which includes the aluminum mold, liquid foam and other materials.

History of Bird Inc.

Bird Inc. stems from Cranston’s lifelong goal of complementing skills with the correct education. After graduating high school during the Vietnam War, he tried college for the first time but felt that sitting through lectures and seminars wasn’t working for him.

“I’m kind of a hands-on learning kind of guy. Sitting and listening to lectures was driving me nuts,” Cranston said.

After two years, he quit college and joined the Army. After serving his country, he moved to the Rocket City, but knew he needed to finish his education to support his growing family. However, after one quarter at the University of Alabama in Huntsville (UAH), he dropped out again. He found success owning a business in the leather craftsman trade, but the country’s economy in the 1980s forced him to pursue other options. He tried college two more times and still didn’t finish.

Eventually, he accepted a job as a technician at NASA’s Marshall Space Flight Center. After 10 years, he was the lead technician, and his lab had a few pending patents on products flying in space.

However, because he didn’t have a college degree, he was told his salary wouldn’t increase without a degree.

Finally, on his fifth attempt at getting a degree, he graduated. His salary doubled immediately.

Cranston had a patent on a foam for the Marshall Space Flight Center’s external tank program. While working with another company, he was developing molds to create a rapid prototype of a crow. That was the spark that inspired Bird Inc.

“I said to myself, ‘I got this mold and this foam. I’m going to combine the two and come up with this manufacturing idea in a classroom and do it in 50 minutes,’” Cranston said. “So, we called it Bird Inc., the 50-Minute Factory.”

Cranston spoke with more than 20,000 students from 1996-2004 and won numerous awards.

Cranston said he’s thrilled to see something he created more than two decades ago receive significant funding and the potential to grow bigger than ever.

However, he said the program boils down to piquing young students’ interest in something they may not have known was possible.

“I believe that hands-on experience will help a child connect with what they are learning in school,” Cranston said. “I think they need to know — just like anyone in that situation — that they are learning a specific topic for a reason. Once they have a goal in mind, it helps them have a purposeful connection to the content.”