For 25 years, experiments on a 1.7-mile loop in Opelika have been changing the way America builds and maintains its highways.

This year marks the 25th anniversary of the National Center for Asphalt Technology’s (NCAT) Test Track — a full-scale pavement testing facility housed within the Samuel Ginn College of Engineering. Now, NCAT is Auburn University’s largest research center and a world leader in asphalt pavement innovation.

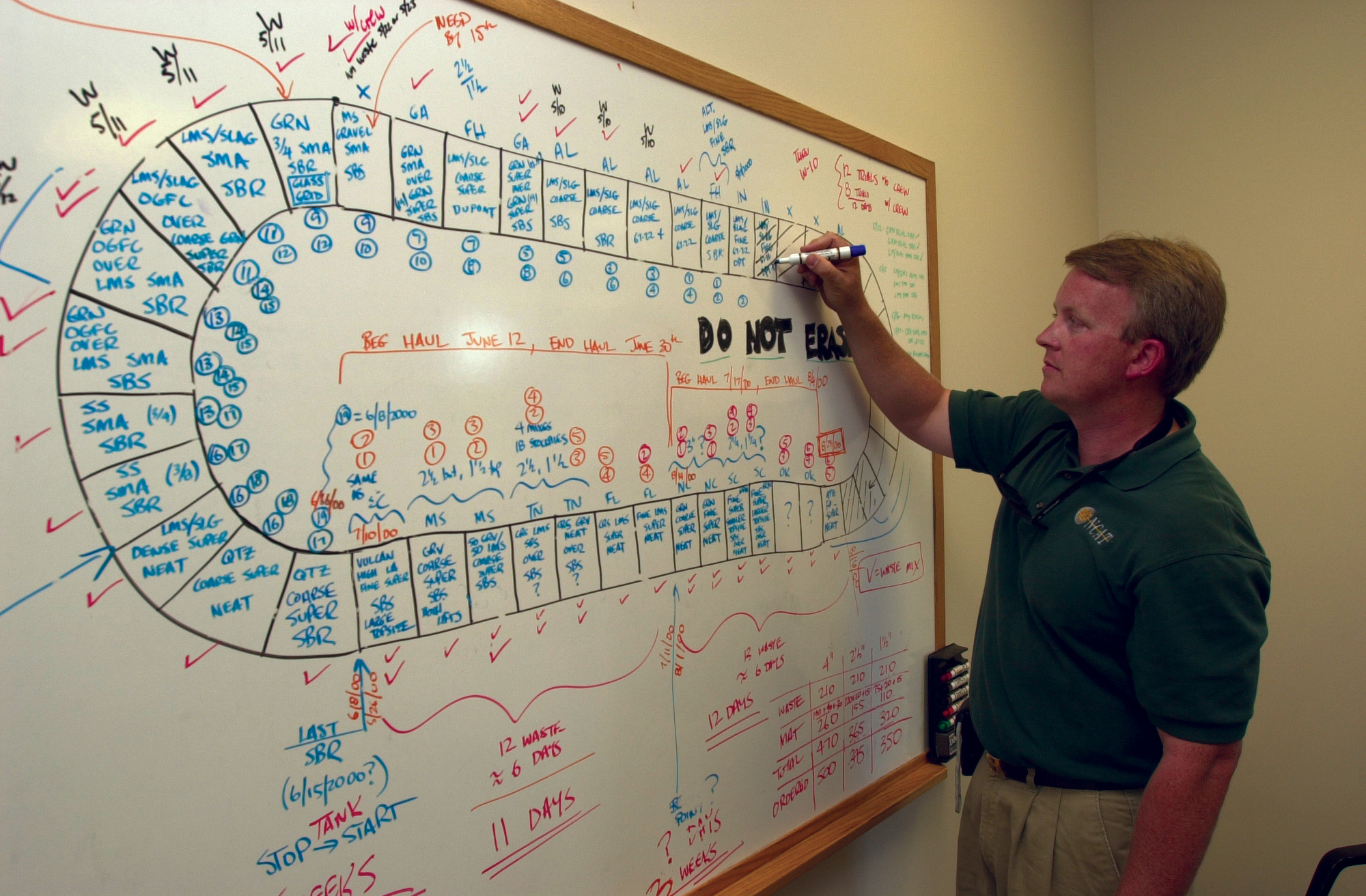

Recognizing the need to bridge the gap between laboratory studies and real-world conditions, the NCAT Board of Directors greenlit a bold idea in 1996: build a facility where materials and designs could be evaluated under controlled, accelerated conditions before reaching public highways.

That vision became reality four years later — in September 2000 — when the Test Track officially opened.

During its lifetime, that 1.7-mile oval has evolved into something much bigger.

For Auburn University, it’s a testament to innovation and research partnerships in action. For the asphalt paving industry, it’s a proving ground that has redefined how roads are built. For the sponsors, it is undeniable proof of the power of research-driven collaboration and purpose.

As the Test Track marks a quarter century of important research, its story is as much about people, partnerships and progress as it is about pavement.

Origins

In 1998, Auburn University purchased 310 acres about 20 minutes from campus to establish NCAT’s full-scale pavement testing facility.

Two years later, the Track was fully constructed and ready for research. Of the 46 sections — each 200 feet in length — 26 were sponsored by state departments of transportation and the Federal Highway Administration, giving the facility immediate national relevance. Its design featured a thick asphalt base and a permeable foundation, intentionally engineered to focus on surface distresses such as rutting and friction, while avoiding deep structural distresses such as fatigue cracking. This ensured that the results could quickly translate into better-performing roads.

The official dedication that October brought together more than 550 attendees from across the country, including members of Congress and leading transportation officials.

While the event drew national attention, it was the early research efforts and collaboration with industry partners that paved the way for the Test Track’s long-term impact. That potential began to take shape as soon as the first trucks started circulating the track.

Keep on trucking

In the third week of September 2000 — a time of boy bands, PalmPilots and CD players — trucks first circled the oval Test Track, kicking off its research journey.

Since then, five triple-loaded trucks have continued to circle the Test Track 16 hours per day, five days a week, applying 10 million equivalent single-axle loads (ESALs) per research cycle.

An ESAL is a unit used to normalize different vehicle loads based on road damage. Each day, the fleet covers the equivalent of a coast-to-coast drive across the U.S. Add those miles together, and the trucks rack up enough distance to circle the globe about once every week and a half.

All without ever leaving Opelika.

“The Track gives us a level of insight into pavement performance that you simply can’t get anywhere else,” said Jason Nelson, NCAT Test Track manager. “The research doesn’t just stay on paper — every mile run at the Test Track generates knowledge that builds safer, longer-lasting roads for millions of travelers.”

Early research results proved the Test Track’s ability to replicate multiple years of interstate traffic in just 24 months, validating the facility as a groundbreaking tool for accelerated pavement testing and delivering what the asphalt industry had long sought: a reliable way to assess pavement performance before innovations reach public highways.

Eight completed research cycles have since driven progress on topics including validating mix design criteria, improving open-graded friction courses, refining pavement thickness design procedures, advancing the use of recycled materials in pavements, evaluating innovative materials for enhanced tire-pavement friction and testing new construction methods and pavement preservation treatments for longer-lasting pavements.

“The Test Track would not be what it is today without the commitment of our sponsors,” said Nathan Moore, assistant director for Test Track research. “Their collaboration ensures that every research cycle addresses the real-world challenges faced by agencies and industry, and their support allows us to deliver solutions that directly impact the future of pavements.

“Their partnership is the foundation of the Test Track’s success and the driving force behind the innovations that have come from it throughout the past 25 years,” he added.

Partnerships that drive progress

At the heart of the Test Track’s operation is its sponsor network, a broad coalition of state DOTs, federal agencies, private contractors and material suppliers.

Since 2000, more than 35 partners have invested in sections of the Track, each pursuing answers to questions about asphalt performance.

This collaborative model ensures that research remains grounded in real-world needs, producing findings that can be applied directly by those funding the work.

Independent evaluations have confirmed the value of this approach, showing savings from more efficient designs and new specifications that ensure better quality, which far outweigh the cost of the research.

For taxpayers, that translates into highways and streets that last longer, perform better and cost less to maintain.

“The Test Track has provided the Tennessee Department of Transportation (TDOT) with a powerful tool for making informed, data-driven decisions in our pavement program,” said Heather Purdy, director of TDOT’s Materials and Tests Division. “The research investments TDOT has made at the track have delivered a substantial return, positively shaping our program.

“We deeply appreciate the dedication and passion of the NCAT team, whose efforts continue to drive innovation and excellence in pavement research,” she added.

TDOT has participated in every research cycle since the Test Track opened. Its work has included Balanced Mix Design (BMD) evaluations, a thick-thin lift study and participation in group experiments with other DOTs. These efforts have supported Tennessee’s expansion of mix design options, validation of its BMD framework and broader improvements to long-term pavement performance.

The track functions as a unique research ecosystem in which sponsors actively shape the direction of studies. They guide experimental designs, introduce new technologies for evaluation and gain early access to results that influence future policy and practice. By sponsoring test sections, agencies can evaluate innovations in a highly controlled environment, thereby reducing risks associated with trying them on their own highway networks.

NCAT’s role is to provide the data collection and monitoring needed to validate performance, while agencies ultimately decide on when and how to adopt the proven solutions. This partnership balances innovation with practicality, creating a pathway for research to move swiftly and confidently from the Test Track to roadways nationwide.

Driving research forward

The launch of the Test Track coincided with another NCAT milestone, the opening of its 40,000-square-foot administrative and laboratory building in 2000, located in Auburn’s South Technology Park, which consolidated the center’s research and training capabilities under one roof for the first time. NCAT’s nationally accredited lab supports implementation by providing high-quality performance testing under realistic aging and loading conditions, helping sponsors make informed engineering decisions about material selection and mix design practices.

Together, the lab and the track create a powerful engine for asphalt research. Laboratory testing enables precise material characterization needed to model pavement responses to loading and environmental changes, while full-scale experiments at the track validate those results under live truck traffic. This dual approach bridges the gap between theory and practice, ensuring that findings can be confidently implemented on real roads with minimal risk.

Fueling the future

Auburn graduate students play a vital role in this work, contributing new ideas and energy while advancing research with NCAT faculty. Their projects range from evaluating innovative asphalt mixtures and sustainability practices to conducting detailed materials testing at the track and in NCAT’s specialized laboratories.

Beyond the lab, students experience the unique culture of NCAT, where close faculty mentorship, industry networking and applied learning create an environment that blends academic rigor with professional impact.

“The Test Track is a place where students learn by doing. They don’t just read about asphalt performance in a textbook — they measure it, analyze it and see it in action,” said Randy West, NCAT director. “That experience helps prepare the next generation of pavement engineers, and our former graduate students are rapidly becoming industry leaders worldwide.

“While NCAT has built a reputation from the quality of our research, our success is truly measured in people.”

A quarter century of impactful research

Twenty-five years of innovation have shaped the Test Track into a cornerstone of asphalt research, and the path forward promises to be just as transformative. Key areas of research on the horizon include:

- Durability solutions, such as thin overlays on worn pavements, and advancing pavement recycling technologies.

- New materials, including additives to resist aging and cracking, using post-consumer recycled materials in pavements for sustainability benefits and developing alternative binders to replace petroleum-based asphalt.

- Safety-focused engineering of vehicle-to-pavement interactions to reduce accidents.

- Foundation improvements through enzyme-based stabilization of weak soils.

These efforts mean stronger, safer and more cost-effective roads that improve daily travel and extend the value of public investment. While the Test Track may be 25 years old, West said it’s not slowing down anytime soon.

“The Test Track and our labs have shown what’s possible when research and real-world needs come together,” West said. “For 25 years, our sponsors and staff have helped turn innovation into practice, and we are confident the next 25 will bring even greater advances for the asphalt community and the traveling public. The questions may change, but the need for answers is constant.”

Every journey on America’s roads carries with it the legacy of Auburn Engineering research. As NCAT prepares to celebrate 40 years as a national research center in 2026, its legacy is defined by innovations that have changed how pavements are engineered nationwide.

After four decades of advancing asphalt research and a quarter century of transformative work at the Test Track, one thing remains clear: all roads lead to Auburn University.